1. Ethylene Oxide Emissions

1.1 What Is Ethylene Oxide (EtO)?

Ethylene oxide (EtO) is a flammable, colorless, and reactive gas. It is a synthetic chemical created as a byproduct of human (i.e., anthropogenic) activities or generated as a natural metabolic product of ethylene by microbes, plants, and animals, including humans (i.e., biogenic).

EtO is one of 188 listed hazardous air pollutants (HAP) covered under Section 112 of the Clean Air Act (CAA). The World Health Organization, the United States Environmental Protection Agency (USEPA), the United States Department of Health and Human Services (HHS), and other health agencies have categorized EtO as a human carcinogen.

EtO is produced and used for various purposes:

- to manufacture other chemicals that are used to make a range of products (e.g., antifreeze, textiles, plastics, detergents, and adhesives)

- to sterilize a wide range of products that are not compatible with other methods of industrial sterilization such as single-use medical devices, custom surgical procedure kits, equipment with integrated electronics, wound care dressings, and other pharmaceutical and biologics applications

- to fumigate and eradicate pests from some foods (e.g., spices)

1.1.1 Why Was This Guide Developed?

EtO is a human carcinogen. Sources of EtO include both large industrial facilities and smaller-scale commercial users of EtO that may be located close to residences, schools, and other nearby workplaces. People also have environmental justice (EJ) concerns about the manufacture and use of EtO in their communities.

In 2016, the USEPA issued a toxicological assessment of EtO that classified it as “carcinogenic to humans” and found it to be a more potent carcinogen via inhalation than previously understood (see Section 2.4 for more information) (USEPA 2016b). EtO in the environment is a result of emissions from the production and processing of industrial chemicals, use of sterilizers, and other possible anthropogenic and natural sources, many of which are still being studied. Based on the updated EtO assessment, USEPA analyses show that EtO emissions may pose a greater public health concern than previously realized (USEPA 2016b).

This guide is intended to help states and other interested parties improve their management of EtO and communicate better about EtO. This guide covers the following topics:

- Properties and effects of EtO

- Regulatory Framework

- Uses and Sources of EtO

- Emissions Control of EtO

- Sampling, Measurements, and Analysis of EtO

- Community Engagement Resources

The Interstate Technology and Regulatory Commission (ITRC) EtO Team has compiled information from a broad range of interested parties, including state and federal governments and industry, to develop this interactive guide. This resource is intended to inform interested parties about important regulatory developments; technical issues surrounding sampling, measurements, and analysis; and effective communication of EtO-related issues. The ITRC acknowledges that there are various viewpoints and expects to update this content as the science continues to develop.

1.1.2 Background EtO

EtO has been detected in many ambient air samples in both urban and rural settings. Currently, the definition of background EtO varies among state, federal, and local entities. For example, background EtO can be defined as EtO detected away from urban areas and emissions sources. USEPA defines background EtO as EtO in the outdoor air that is not clearly linked to a particular industrial facility (USEPA 2023a, USEPA 2023i). Please refer to state resources to verify how background EtO is defined in your area. In this guide, background EtO is defined as EtO in ambient air that is not clearly linked to any known or suspected source, such as a chemical plant or commercial sterilizer. Challenges with EtO sampling and data interpretation are explained further in Section 6

Interactive EtO Guidance Roadmap.

Click on a hexagon to be moved to that section.

2. Introduction

2.1 Physical and Chemical Properties

EtO is a colorless, flammable, and reactive gas with a sweet odor. Most people can only smell it once the concentration is above thresholds associated with acute effects. Therefore, odor is not a reliable indicator of exposure to EtO (California Department of Health Services 1991). It is highly soluble in water and possesses a high vapor pressure.

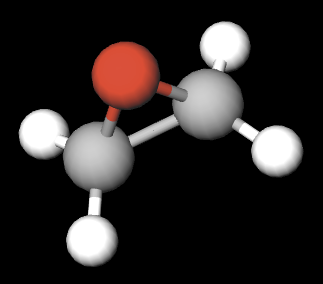

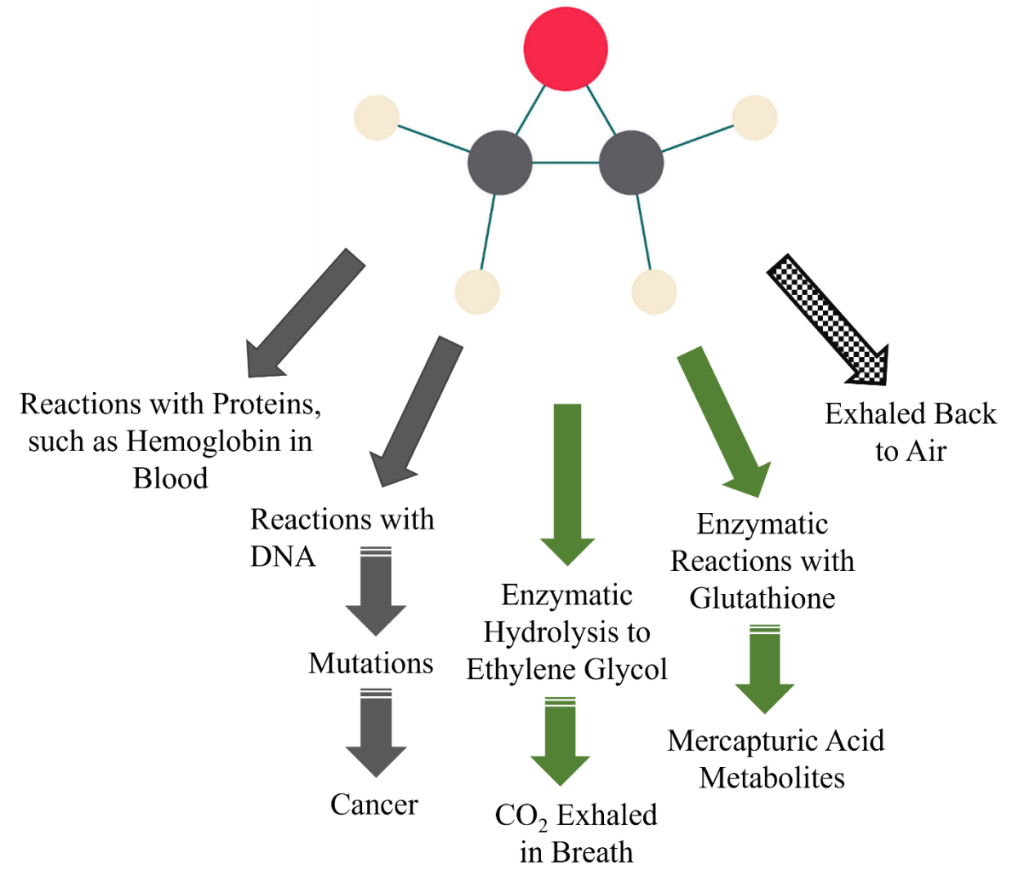

The EtO molecular structure is shown in Figure 1. It is composed of an oxygen atom (red) that is covalently bound to each of two carbon atoms (gray). Together, these form a three-membered ring of the chemical epoxide group. The carbon atoms are also each covalently linked to two hydrogen molecules (white). The epoxide group is reactive and leads to the formation of chemical products as well as DNA and protein adducts. Table 1 lists the physical and chemical properties of EtO.

2.2 Production and Industrial Use

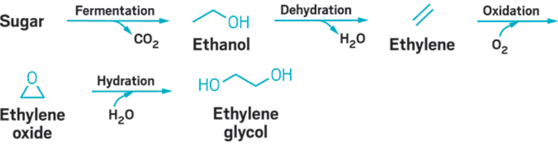

EtO is both a natural substance and a synthetic substance. The quantity of EtO produced naturally by the metabolism of ethylene in microbes, plants, and animals (including humans) is currently unknown (see the appendix for more information). It can emanate from water-logged soil, manure, and sewage sludge where it may be produced by microbial activity (Liteplo, Meek, and Lewis 2003).

Synthetic EtO is primarily produced through the oxidation of ethylene with a silver catalyst. In 2019, the United States produced 2.92 million metric tons of EtO, and the total production capacity is expected to increase due to market demand (ACC 2019a). More than 97% of the amount produced is used as a chemical intermediate for the production of other chemicals, such as (mono)ethylene glycol (MEG), ethoxylates, ethanolamines, glycol ethers, and polyether polyols (ACC 2019a). Less than 1% of produced EtO is used as a fumigant, to sterilize food (spices) and cosmetics, and to sterilize medical and surgical equipment and plastic devices that cannot be sterilized by heat or steam. EtO is widely used at both commercial sterilization facilities and hospitals and is an effective sterilant gas that can penetrate packaging and destroy bacteria and viruses (ATSDR 2022d).

EtO is a raw material converted through manufacturing into a variety of products used in everyday life (Dever et al. 2000). The manufacturing process converts EtO into inert materials that are considered safe for consumers when used as intended. For example, a significant portion (34%) of all EtO that is used in manufacturing is converted into MEG for use as an antifreeze. The remainder goes to broader glycols production (ACC 2019a).

Approximately 15% of EtO used in manufacturing is used to produce various ethoxylate surfactants/detergents (captured within the ethoxylates category) and other derivatives, including polyethylene glycols, glycol ethers, ethanolamines, polyurethane foam, and mixed polyglycols (ACC 2022).

The products that are made from EtO raw material are used in many commercial and industrial applications, including the following (ACC 2019b):

- adhesives, paints, and inks

- appliance insulation

- architectural coatings

- automotive and architectural glass

- automotive seating

- carpet backing and furniture cushioning

- commercial and residential roofing

- hydraulic and brake fluids

- lubricants

- metal and industrial cleaning

- motor vehicle antifreezes

- natural gas and oil industry products

- personal care products

- pharmaceuticals

- polyester

- polyether polyols

- polymers and resins

- safety glass

- textile additives

2.2.1 Additional Uses

Various derivatives of EtO are used as precursors to or as final products in applications such as CO2 scrubbing, water treatment, solvents, plasticizers, wetting agents, emulsifiers, and dispersants (Faveere et al. 2021). Ethoxylation derivatives, called demulsifiers, are used in corn oil extraction processes (ACC 2023b). EtO is also used in the corn refining industry to produce industrial hydroxyethylated starch that is widely used in surface sizing and coating paper (Corn Refiners Association 2006). EtO derivatives are also used as raw materials in the manufacture of lithium-ion batteries installed in electric vehicles (ACC 2023a).

2.3 Emission and Fate

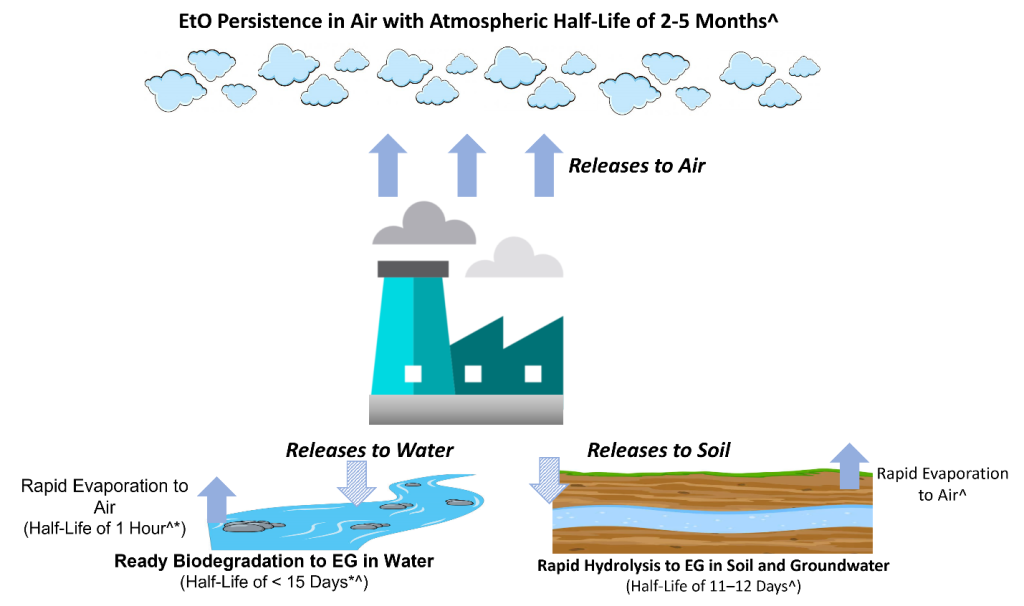

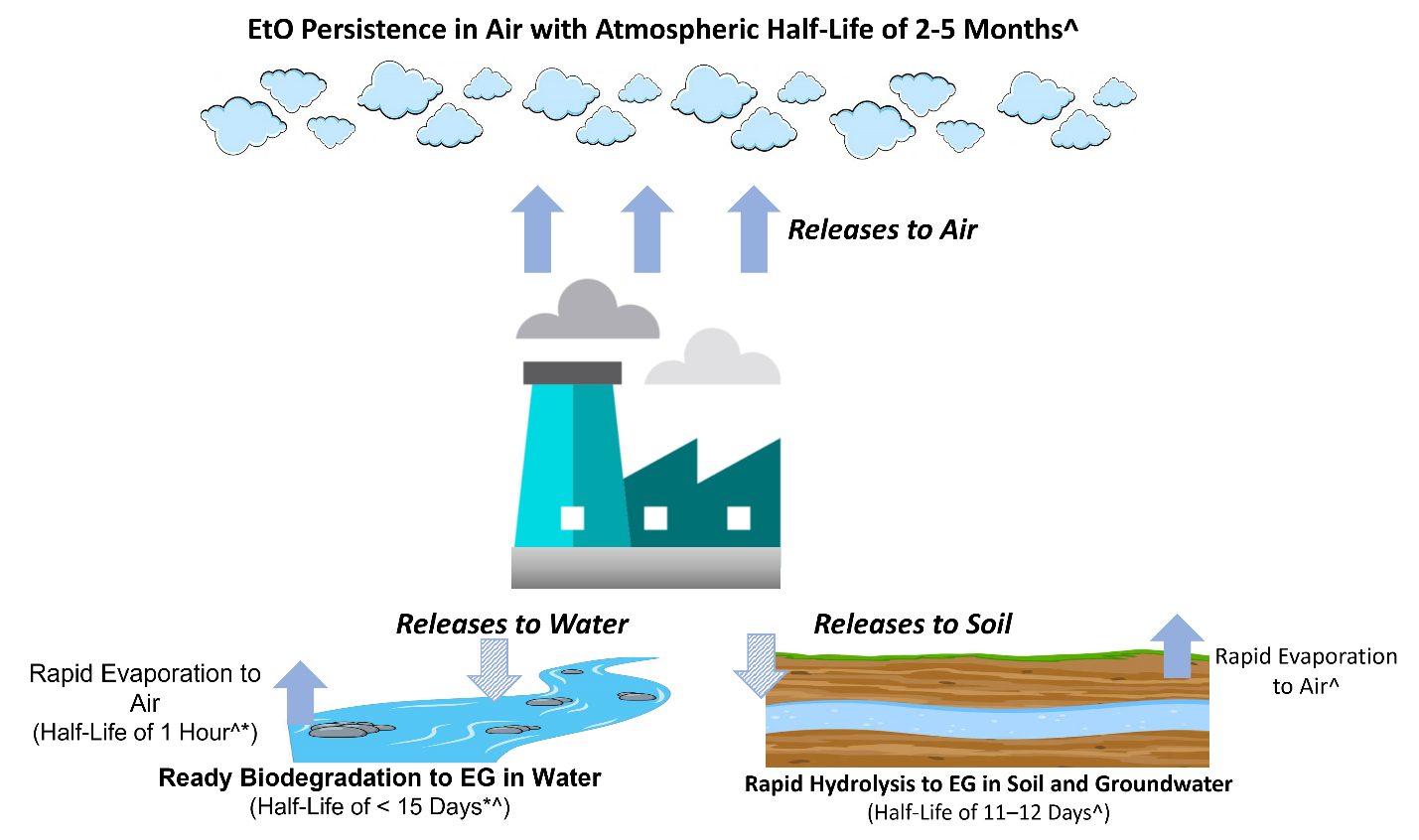

The environmental transport of EtO is primarily through the air as a gas at atmospheric pressure and room temperature. In the air, EtO undergoes measurable rates of degradation. Oxidation via hydroxyl radical formation is the most common degradation pathway into carbon dioxide and water. The estimated half-life of this reaction ranges from 2 to 5 months (ATSDR 2022d). Laboratory estimates of the half-life of other reactions of EtO in the atmosphere vary widely. The reaction with the hydroxyl radical may have a half-life of 1 to 12 months (Liteplo, Meek, and Lewis 2003), and ultraviolet-catalyzed oxidation in the presence of oxygen and nitrogen dioxide may occur (ATSDR 2022d).

Figure 2 illustrates the environmental fate of released EtO. Regardless of the source of EtO, air is the predominant environmental medium to which it partitions and persists. Releases to water and soil (e.g., spill) are less frequent and are minor contributors of EtO to the environment. Evaporation of EtO from soil and water are not expected to substantially contribute to the air/ambient environment (ATSDR 2022d, Conway et al. 1983).

Figure 2. Environmental fate of EtO with information on environmental half-lives.

Notes: Arrows are not to scale. Solid arrows represent the major environmental air releases for EtO accumulation. Hatched arrows indicate minor environmental water and soil releases where potential EtO accumulation does not persist. In water and soil, EtO is hydrolyzed (biodegrades) to (mono)ethylene glycol (MEG) or to MEG and ethylene chlorohydrin (ECH) in salt water. Half-life sources: ^ATSDR (2022a), *Conway and colleagues (1983).

Source: Joanna Klapacz/DOW. Used with permission.

Toxics Release Inventory Reported EtO Emissions

In 2021, 155,498 pounds of EtO was emitted to air (USEPA 2022j).

Most emissions of EtO occur during production, usage, storage, and handling in commercial and industrial settings. Such emissions originate from stacks and vents and from fugitive sources (such as building openings and equipment leaks) at regulated and unregulated facilities The USEPA has two inventories, the Toxics Release Inventory (TRI) and the National Emissions Inventory (NEI), which collect data from industry-reported emissions of EtO to air (USEPA 2023v, 2023ag). These two inventories have different reporting criteria and have not always required reporting of EtO data from all sectors. For facilities common to both TRI and NEI, air emissions may be the same or differ based on the criteria. NEI includes EtO emissions at facilities that do not report EtO emissions to TRI. NEI also includes EtO emissions not associated with individual facilities, referred to as nonpoint emissions.

EtO is highly soluble in water but may volatilize from water due to its high vapor pressure. Conway and colleagues (1983) reported that about 95% of EtO mixed with water volatilizes within four hours and thus would not be prevalent in environmental water sources. EtO in water also degrades via hydrolysis and reaction with anions, leading to the formation of glycols and halogenated alcohols. These degrade into simpler molecules such as carbon dioxide and water. The half-lives of these reactions range from a few hours to less than 15 days, depending on environmental conditions. EtO also undergoes aerobic and anaerobic biodegradation, with a half-life in wastewater treatment systems of about 20 days (ATSDR 2022d).

Due to its chemical and physical properties, EtO in soil is expected to volatilize, migrate through the soil, or be removed by runoff during rainstorms (ATSDR 2022d). Further, EtO in soil is expected to undergo hydrolysis and biodegradation, similar to EtO in water bodies, as well as to react with mineral surfaces, although again, studies are lacking (ATSDR 2022d) (see Figure 2).

Some industrial sources discharge EtO in wastewater. The TRI shows 2,665 pounds of EtO were discharged to surface waters in 2019. This includes releases to wastewater treatment and publicly owned treatment works. Some industrial sources release EtO to the soil. The TRI shows 30,723 pounds of EtO were released to soils in 2019. In addition, although EtO is not approved as a soil fumigant, soils may be exposed via rainfall where EtO is entrained from the rain and deposited on the ground or via uncontrolled discharges of liquid wastes (ATSDR 2022d).

2.1 Physical and Chemical Properties

EtO is a colorless, flammable, and reactive gas with a sweet odor. Most people can only smell it once the concentration is above thresholds associated with acute effects. Therefore, odor is not a reliable indicator of exposure to EtO (California Department of Health Services 1991). It is highly soluble in water and possesses a high vapor pressure.

The EtO molecular structure is shown in Figure 1. It is composed of an oxygen atom (red) that is covalently bound to each of two carbon atoms (gray). Together, these form a three-membered ring of the chemical epoxide group. The carbon atoms are also each covalently linked to two hydrogen molecules (white). The epoxide group is reactive and leads to the formation of chemical products as well as DNA and protein adducts. Table 1 lists the physical and chemical properties of EtO.

Table 1. Physical and chemical properties of EtO

| Molecular Formula | C2H4O |

| Molecular Weight | 44.053 grams/mole |

| CAS # | 75-21-8 |

| Melting Point | −111.6°C |

| Boiling Point | 10.4°C |

| Density at 10°C | 0.8824 |

| Relative Density | 0.9 |

| Vapor Pressure at 25°C | 1,255 mm Hg (146 kPa at 20°C, 1.46 atm) |

| Henry’s Law Constant at 25°C | 1.48 × 10-4 atm-m3/mole |

| Water Solubility at 20°C | 1 × 106 mg/liter |

| Odor Thresholds | Water: 140 mg/liter Air: 787 mg/m3 (433 ppm) |

| Autoignition Temperature | 429°C |

| Flashpoint | < −18°C |

| Flammability / Explosive Limits | Lower: 3% Upper: 100% |

Sources: ATSDR (2022a), OSHA (2023b), USEPA (2020c), and sources therein.

Notes: atm = standard atmospheric pressure, CAS # = Chemical Abstracts Service Number, kPa = kilopascal, m = meter, mg = milligrams, mm Hg = millimeters of mercury, ppm = parts per million.

2.2 Production and Industrial Use

EtO is both a natural substance and a synthetic substance. The quantity of EtO produced naturally by the metabolism of ethylene in microbes, plants, and animals (including humans) is currently unknown (see the appendix for more information). It can emanate from water-logged soil, manure, and sewage sludge where it may be produced by microbial activity (Liteplo, Meek, and Lewis 2003).

Synthetic EtO is primarily produced through the oxidation of ethylene with a silver catalyst. In 2019, the United States produced 2.92 million metric tons of EtO, and the total production capacity is expected to increase due to market demand (ACC 2019a). More than 97% of the amount produced is used as a chemical intermediate for the production of other chemicals, such as (mono)ethylene glycol (MEG), ethoxylates, ethanolamines, glycol ethers, and polyether polyols (ACC 2019a). Less than 1% of produced EtO is used as a fumigant, to sterilize food (spices) and cosmetics, and to sterilize medical and surgical equipment and plastic devices that cannot be sterilized by heat or steam. EtO is widely used at both commercial sterilization facilities and hospitals and is an effective sterilant gas that can penetrate packaging and destroy bacteria and viruses (ATSDR 2022d).

EtO is a raw material converted through manufacturing into a variety of products used in everyday life (Dever et al. 2000). The manufacturing process converts EtO into inert materials that are considered safe for consumers when used as intended. For example, a significant portion (34%) of all EtO that is used in manufacturing is converted into MEG for use as an antifreeze. The remainder goes to broader glycols production (ACC 2019a).

Approximately 15% of EtO used in manufacturing is used to produce various ethoxylate surfactants/detergents (captured within the ethoxylates category) and other derivatives, including polyethylene glycols, glycol ethers, ethanolamines, polyurethane foam, and mixed polyglycols (ACC 2022).

The products that are made from EtO raw material are used in many commercial and industrial applications, including the following (ACC 2019b):

- adhesives, paints, and inks

- appliance insulation

- architectural coatings

- automotive and architectural glass

- automotive seating

- carpet backing and furniture cushioning

- commercial and residential roofing

- hydraulic and brake fluids

- lubricants

- metal and industrial cleaning

- motor vehicle antifreezes

- natural gas and oil industry products

- personal care products

- pharmaceuticals

- polyester

- polyether polyols

- polymers and resins

- safety glass

- textile additives

2.2.1 Additional Uses

Various derivatives of EtO are used as precursors to or as final products in applications such as CO2 scrubbing, water treatment, solvents, plasticizers, wetting agents, emulsifiers, and dispersants (Faveere et al. 2021). Ethoxylation derivatives, called demulsifiers, are used in corn oil extraction processes (ACC 2023b). EtO is also used in the corn refining industry to produce industrial hydroxyethylated starch that is widely used in surface sizing and coating paper (Corn Refiners Association 2006). EtO derivatives are also used as raw materials in the manufacture of lithium-ion batteries installed in electric vehicles (ACC 2023a).

2.3 Emission and Fate

The environmental transport of EtO is primarily through the air as a gas at atmospheric pressure and room temperature. In the air, EtO undergoes measurable rates of degradation. Oxidation via hydroxyl radical formation is the most common degradation pathway into carbon dioxide and water. The estimated half-life of this reaction ranges from 2 to 5 months (ATSDR 2022d). Laboratory estimates of the half-life of other reactions of EtO in the atmosphere vary widely. The reaction with the hydroxyl radical may have a half-life of 1 to 12 months (Liteplo, Meek, and Lewis 2003), and ultraviolet-catalyzed oxidation in the presence of oxygen and nitrogen dioxide may occur (ATSDR 2022d).

Figure 2 illustrates the environmental fate of released EtO. Regardless of the source of EtO, air is the predominant environmental medium to which it partitions and persists. Releases to water and soil (e.g., spill) are less frequent and are minor contributors of EtO to the environment. Evaporation of EtO from soil and water are not expected to substantially contribute to the air/ambient environment (ATSDR 2022d, Conway et al. 1983).

Toxics Release Inventory Reported EtO Emissions

In 2021, 155,498 pounds of EtO was emitted to air (USEPA 2022j).

Most emissions of EtO occur during production, usage, storage, and handling in commercial and industrial settings. Such emissions originate from stacks and vents and from fugitive sources (such as building openings and equipment leaks) at regulated and unregulated facilities The USEPA has two inventories, the Toxics Release Inventory (TRI) and the National Emissions Inventory (NEI), which collect data from industry-reported emissions of EtO to air (USEPA 2023v, 2023ag). These two inventories have different reporting criteria and have not always required reporting of EtO data from all sectors. For facilities common to both TRI and NEI, air emissions may be the same or differ based on the criteria. NEI includes EtO emissions at facilities that do not report EtO emissions to TRI. NEI also includes EtO emissions not associated with individual facilities, referred to as nonpoint emissions.

EtO is highly soluble in water but may volatilize from water due to its high vapor pressure. Conway and colleagues (1983) reported that about 95% of EtO mixed with water volatilizes within four hours and thus would not be prevalent in environmental water sources. EtO in water also degrades via hydrolysis and reaction with anions, leading to the formation of glycols and halogenated alcohols. These degrade into simpler molecules such as carbon dioxide and water. The half-lives of these reactions range from a few hours to less than 15 days, depending on environmental conditions. EtO also undergoes aerobic and anaerobic biodegradation, with a half-life in wastewater treatment systems of about 20 days (ATSDR 2022d).

Due to its chemical and physical properties, EtO in soil is expected to volatilize, migrate through the soil, or be removed by runoff during rainstorms (ATSDR 2022d). Further, EtO in soil is expected to undergo hydrolysis and biodegradation, similar to EtO in water bodies, as well as to react with mineral surfaces, although again, studies are lacking (ATSDR 2022d) (see Figure 2).

Some industrial sources discharge EtO in wastewater. The TRI shows 2,665 pounds of EtO were discharged to surface waters in 2019. This includes releases to wastewater treatment and publicly owned treatment works. Some industrial sources release EtO to the soil. The TRI shows 30,723 pounds of EtO were released to soils in 2019. In addition, although EtO is not approved as a soil fumigant, soils may be exposed via rainfall where EtO is entrained from the rain and deposited on the ground or via uncontrolled discharges of liquid wastes (ATSDR 2022d).

Figure 1. EtO compound molecule.

Source: Kristi Beck/Maricopa County Air Quality Department (created at MolView.org). Used with permission.

Figure 2. Environmental fate of EtO with information on environmental half-lives.

Notes: Arrows are not to scale. Solid arrows represent the major environmental air releases for EtO accumulation. Hatched arrows indicate minor environmental water and soil releases where potential EtO accumulation does not persist. In water and soil, EtO is hydrolyzed (biodegrades) to (mono)ethylene glycol (MEG) or to MEG and ethylene chlorohydrin (ECH) in salt water. Half-life sources: ^ATSDR (2022a), *Conway and colleagues (1983).

Source: Joanna Klapacz/DOW. Used with permission.

2.4 Health Effects

Inhalation is the primary EtO exposure route. Occupational exposure to EtO is possible for people working where EtO is produced or used, such as chemical plants or commercial or industrial sterilizing facilities. These occupational exposures may be higher than exposures for people not working with EtO. Additionally, individuals who live near facilities that release EtO may be exposed. Biomarker data for EtO exposure for the U.S. general population have been monitored by the United States Centers for Disease Control and Prevention (CDC) in the National Health and Nutrition Examination Survey (NHANES) cycles 2013–2014 and 2015–2016 and are publicly available (CDC 2022). The information presented in these data are based on hemoglobin biomarker levels (i.e., hemoglobin adducts). Lifestyle choices may also contribute to higher total EtO exposure and adduct levels (e.g., higher levels in smokers vs. lower levels in nonsmokers) (Kirman et al. 2021). Due to its chemical and physical properties, EtO is expected to persist in air for 2–5 months but not in other environmental media, such as soil and water (ATSDR 2022d). Current data suggest that EtO would not remain in or on food or dissolved in water long enough to be ingested.

2.4.1 Short-term Health Effects

High concentrations of EtO can cause noncancer health effects. Studies of workers exposed to high concentrations of EtO in the air for short or long (chronic) periods of time have reported respiratory, eye, and skin irritation; headaches; memory loss; numbness; nausea; and vomiting. Studies of workers routinely exposed to EtO above occupational exposure limits (OELs) in the air have reported evidence of cellular changes and effects on the blood (ATSDR 2022a). More information on OELs can be found in the National Institute for Occupational Safety and Health (NIOSH) pocket guide to chemical hazards (NIOSH 2019). More studies are needed to better understand the impacts of EtO exposure on pregnant people (ATSDR 2022c). Laboratory animal studies show associations between higher-dose EtO exposures and reproductive and developmental effects, including fetal loss (ATSDR 2022d). The short-term (acute, 1-hour) estimated concentrations of EtO in ambient air are ordinarily well below concentrations that may cause immediately serious or long-lasting noncancer health effects (ATSDR 2022a).

2.4.2 Long-term Health Effects

The HHS has classified EtO as “known to be a human carcinogen” (HHS 2021). The USEPA has characterized EtO as “carcinogenic to humans” by the inhalation exposure route (USEPA 2016b). The International Agency for Research on Cancer (IARC) has designated EtO as “carcinogenic to humans (Group 1)” (IARC 1987, 2012). EtO is also known to be mutagenic in a large number of living organisms and to induce chromosome damage (USEPA 2016b). Occupational studies indicate that humans with long-term (years or decades) cumulative exposure to elevated EtO concentrations have an increased risk of lymphohematopoietic cancers, including non-Hodgkin’s lymphoma, myeloma, and lymphocytic leukemia (Steenland, Stayner, and Deddens 2004, Steenland et al. 2003). USEPA’s 2016 Integrated Risk Information System (IRIS) assessment concluded that long-term exposure to elevated EtO concentrations increased the risk of breast cancer in women (ATSDR 2022a, Steenland, Stayner, and Deddens 2004, Steenland et al. 2003). Similar cancers were found in animal studies (ATSDR 2022a). The Texas Commission on Environmental Quality (TCEQ) concluded that EtO is “likely to be carcinogenic to humans,” particularly for lymphohematopoietic cancers, but that there was insufficient evidence to link EtO with human breast cancer (TCEQ 2020a).

The USEPA IRIS program used available studies of workers to develop a cancer risk value for inhalation exposure to EtO to be applied at lower levels more typical of outdoor air concentrations (USEPA 2023r). A cancer risk value relates the concentration in the air to the risk of developing cancer in a lifetime. This value was reassessed and updated in 2016. The development of inhalation unit risk values requires assumptions, interpretations of the data, and judgment, which can lead to different conclusions. For example, the TCEQ and the California Environmental Protection Agency (California EPA) have developed their own cancer risk values for EtO. On December 21, 2022, the USEPA issued a final decision to continue to use the USEPA IRIS value for federal regulation because the USEPA IRIS value was developed using an approach supported by the Science Advisory Board for selecting dose-response values for the CAA Section 112(f)(2) risk reviews (USEPA 2022j).

This guide is meant to be informative and is intended to present a variety of available information. Thus, this guide presents resources developed by state and federal agencies. Although these approaches may differ, the risk assessments used to support federal regulations are often based on the USEPA IRIS risk value for EtO.

Links to examples of the different approaches to deriving lifetime estimated cancer risk values are provided below:

- USEPA (USEPA 2016a)

- California EPA (draft document currently under review) (California EPA 2023)

- TCEQ (TCEQ 2020b)

3. Regulatory Framework

3.1 EtO History

In 1859, French chemist Charles-Adolphe Wurtz first synthesized EtO. Since then, it has been used in many different industrial and commercial processes. Commercial production of EtO began in 1914 and achieved industrial importance during World War I as a precursor to the coolant MEG and the chemical weapon mustard gas (ACS 2019, NWE 2017).

In 1931, French chemist Theodore Lefort patented an efficient direct oxidated method of preparing EtO. In 1937 Union Carbide opened a processing plant using this method (NWE 2017).

In 1938, American Chemist Lloyd Hall received a patent for sterilization by EtO for the preservation of spices (Figure 3). By 1940, this process was used in a vacuum chamber for spices and other food preservatives (African American Registry 2022).

By 1948, the health effects experienced by those exposed to EtO had been observed, and a study found that it potentially causes cancer (USEPA 2016b). Despite this study, EtO became a common sterilizer of medical instruments by 1950.

In 1985 USEPA, through IRIS, first quantified the relationship between the concentration of EtO in air and the potential risk of cancer and estimated the cancer unit risk (Gray, Harris, and Santodonato 1985). In 1986, Congress approved the Emergency Planning and Community Right-To-Know Act requiring industry to report the storage, use, and release of hazardous substances. USEPA compiles an annual TRI that includes EtO and is available to the public. California declared EtO as a human carcinogen in 1987 (USEPA 2023ag). In 1990, USEPA listed EtO as one of the 188 HAP.

During 2003 and 2004, NIOSH reported that workers exposed to high levels of EtO may be at an increased risk for breast cancer and lymphomas (CDC 2020). In 2006 USEPA released a first draft of its scientific review that concluded EtO was a human carcinogen. Based on the additional scientific data that became available and updates to data evaluation methods, USEPA published a new IRIS assessment in 2016 (USEPA 2016b). The new assessment reclassified EtO from a “probable carcinogen” to “carcinogenic to humans” and indicated a greater cancer potency as shown by the revised inhalation unit risk estimate (USEPA 2016b).

3.1 EtO History

In 1859, French chemist Charles-Adolphe Wurtz first synthesized EtO. Since then, it has been used in many different industrial and commercial processes. Commercial production of EtO began in 1914 and achieved industrial importance during World War I as a precursor to the coolant MEG and the chemical weapon mustard gas (ACS 2019, NWE 2017).

In 1931, French chemist Theodore Lefort patented an efficient direct oxidated method of preparing EtO. In 1937 Union Carbide opened a processing plant using this method (NWE 2017).

In 1938, American Chemist Lloyd Hall received a patent for sterilization by EtO for the preservation of spices (Figure 3). By 1940, this process was used in a vacuum chamber for spices and other food preservatives (African American Registry 2022).

By 1948, the health effects experienced by those exposed to EtO had been observed, and a study found that it potentially causes cancer (USEPA 2016b). Despite this study, EtO became a common sterilizer of medical instruments by 1950.

In 1985 USEPA, through IRIS, first quantified the relationship between the concentration of EtO in air and the potential risk of cancer and estimated the cancer unit risk (Gray, Harris, and Santodonato 1985). In 1986, Congress approved the Emergency Planning and Community Right-To-Know Act requiring industry to report the storage, use, and release of hazardous substances. USEPA compiles an annual TRI that includes EtO and is available to the public. California declared EtO as a human carcinogen in 1987 (USEPA 2023ag). In 1990, USEPA listed EtO as one of the 188 HAP.

During 2003 and 2004, NIOSH reported that workers exposed to high levels of EtO may be at an increased risk for breast cancer and lymphomas (CDC 2020). In 2006 USEPA released a first draft of its scientific review that concluded EtO was a human carcinogen. Based on the additional scientific data that became available and updates to data evaluation methods, USEPA published a new IRIS assessment in 2016 (USEPA 2016b). The new assessment reclassified EtO from a “probable carcinogen” to “carcinogenic to humans” and indicated a greater cancer potency as shown by the revised inhalation unit risk estimate (USEPA 2016b).

Figure 3. Spices.

Source: Microsoft Stock Images.

3.2 What Prompted USEPA Action to Revise EtO Regulations?

As discussed in Section 2.4, the USEPA IRIS published the final toxicological assessment of EtO in 2016 (USEPA 2016b).

Follow these links for the results of AirToxScreen (formerly known as NATA)

For more information on AirToxScreen, see Section 4.2.

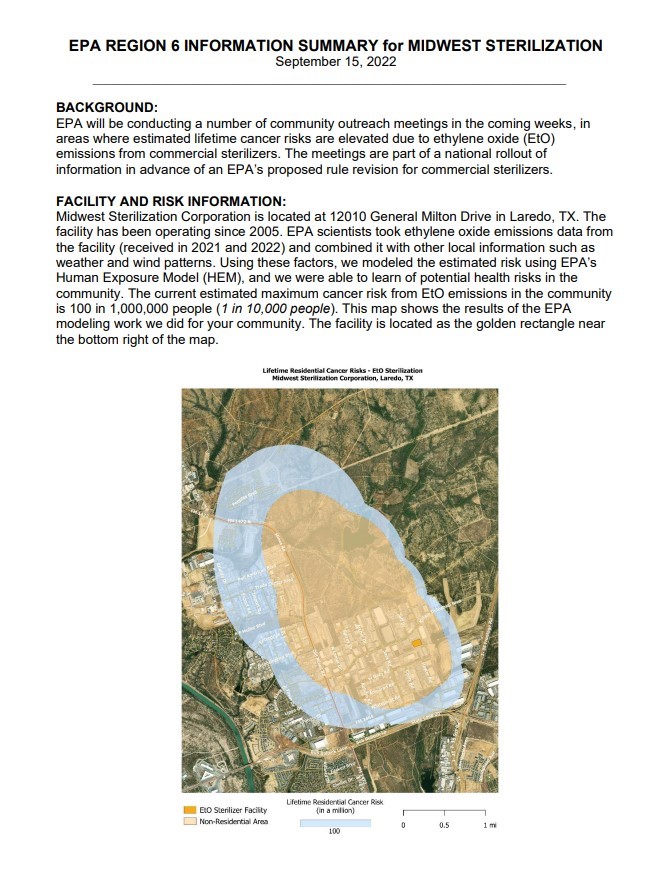

USEPA first used the new IRIS value to estimate EtO risks across the United States in the National Air Toxics Assessment (NATA) released in August 2018. NATA provides screening-level estimates of cancer risk and noncancer health hazard from inhalation of air toxics. These screening-level estimates can be used to identify where additional review and refined risk assessments are warranted. The NATA released in 2018, which used 2014 facility data, identified several areas in the United States as potentially having cancer risks greater than 100 in 1 million (1×10−4) from long-term exposure (70 years) to EtO. These areas had not been identified in previous versions of NATA because the 1985 inhalation unit risk estimate had been based on rodent cancer data available at the time. An increased cancer risk estimate of 100 in 1 million (1×10−4) over a lifetime is ordinarily the upper end of the range of acceptable risk used for regulatory decision-making under CAA Section 112. Commercial sterilizing and chemical manufacturing facilities that use EtO self-reported emissions that were used to identify areas where there is increased risk.

USEPA gathered information nationwide from 2018–2019 on the facilities using EtO and began to evaluate potential rule revisions. In 2021, USEPA expanded the TRI reporting requirements for EtO to include contract sterilization facilities and MEG releases (USEPA 2022f).

3.3 Why are EtO Regulations Important?

Under the CAA, USEPA is required to promulgate National Emission Standards for Hazardous Air Pollutants (NESHAP), which includes categories of stationary sources of emissions of the 188 listed HAPs in Section 112(b) of the CAA. Under Section 112(c) of the CAA, a substance may be added to the list of HAPs if it is an air pollutant that is “known or suspected to cause cancer or other serious health effects, such as reproductive effects or birth defects, or adverse environmental effects” (USEPA 2023w). For more detailed information, visit the USEPA NESHAP page (USEPA 2023u).

Sources subject to NESHAPs are typically “required to perform an initial performance test to demonstrate compliance. To demonstrate continuous compliance, sources are generally required to monitor control device operating parameters, which are established during the initial performance test. Sources may also be required to install and operate continuous emission monitors or perform periodic emissions testing to demonstrate compliance. Consistent with USEPA’s Clean Air Act Stationary Source Compliance Monitoring Strategy, NESHAP sources that meet the Clean Air Act definition of ‘major source’ generally receive a full compliance evaluation by the state or regional office at least once every two years” (USEPA 2023w).

National regulations are important because (1) the regulations are developed from information gathered across the country; (2) the regulations create clear, consistent requirements for the regulated industry, creating a level playing field for facilities and regulators; (3) USEPA has resources to study the issues that may not be available at the state level; and (4) the broader benefits of regulating a facility can be weighed against the potential risk from the facility operations.

3.4 Regulations

3.4.1 Chemical Sterilization/Fumigation

The FDA states that, “Use of ethylene oxide is a well-established and scientifically-proven method of preventing harmful microorganisms from reproducing and causing infections without degrading the product, unlike some other sterilization methods.” Further, “more than 20 billion devices sold in the U.S. every year are sterilized with ethylene oxide, accounting for approximately 50% of devices that require sterilization. These devices range from wound dressings to more specialized devices, such as stents, as well as kits used in routine hospital procedures or surgeries that include multiple components made from different materials. Inadequate sterilization can lead to life-threatening infections in patients undergoing a wide range of medical procedures” (FDA 2022).

For more information on the FDA and EtO, visit: Sterilization for Medical Devices (FDA 2023b)

The NESHAP for Ethylene Oxide Emissions Standards for Commercial Sterilization and Fumigation Operations found in 40 Code of Federal Regulations (CFR) Part 63, Subpart O establishes emission standards for major and area sources that use at least 1 ton of EtO in sterilization or fumigation operations in any 12-month period (59 FR 6289 1994). The standards require existing and new major sources to control emissions to the level achievable by the maximum achievable control technology (MACT). The regulation also requires existing and new area sources to control emissions using generally available control technology. A proposed revision was released on April 11, 2023. Additional Resources on the proposed rule can be found on USEPA’s website (USEPA 2023z).

In 2022, USEPA released new information related to the impacts of certain EtO sterilization facilities on surrounding communities (USEPA 2023m). A national public webinar was held on August 10, 2022, a recording of which can be found here (USEPA 2022h). The new information website also includes the locations and names of commercial sterilizers where the estimated excess lifetime cancer risk associated with exposures from EtO emissions is at or above 100 in 1 million for people living nearby (USEPA 2023m). USEPA stated that they plan to engage with each of the communities located in the elevated risk areas by hosting public meetings for each location. During the second half of 2022, these community engagement efforts were conducted by USEPA.

As of December 2021, USEPA announced that they have broadened reporting on EtO. This change included extending the reporting requirements to 29 contract sterilization facilities that are now subject to the Toxics Release Inventory (TRI) (USEPA 2022f).

Those interested in information about EtO outreach can sign up on the USEPA EtO information page to receive the most up-to-date information (USEPA 2023m).

3.4.2 Miscellaneous Organic Chemical Manufacturing NESHAP

The Miscellaneous Organic NESHAP (MON) found in 40 CFR Part 63 Subpart FFFF establishes emission limits and work practice standards for “new and existing miscellaneous organic chemical manufacturing process units, wastewater treatment and conveyance systems, transfer operations, and associated ancillary equipment” (USEPA 2023t). Section 112(d) of the CAA requires all major sources to meet HAP emission standards and apply the MACT.

3.4.3 Synthetic Organic Chemical Manufacturing Industry / Hazardous Organic NESHAP

The Synthetic Organic Chemical Manufacturing Industry NESHAP (SOCMI), commonly known as the Hazardous Organic NESHAP (HON), found in 40 CFR Part 63 consists of four subparts (Subparts F, G, H, and I). Subpart F provides the applicability criteria for the HON and requires that “owners and operators of HON sources comply with subparts G and H, and specifies general recordkeeping and reporting requirements (USEPA 2023t). The specific control, monitoring, reporting, and recordkeeping requirements are stated in subpart G for process vents, storage vessels, transfer racks, and wastewater streams, and in subpart H for equipment leaks. Subpart I provides the applicability criteria for the non-HON processes subject to the negotiated regulation for equipment leaks and requires owners and operators to comply with subpart H” (USEPA 2023ae). On April 25, 2023, USEPA released a proposed rule and held a public webinar on the proposed updates to the standards. Additional resources related to the proposed rule can be found at the HON link above.

3.4.4 Hospital Sterilizers NESHAP

The NESHAP found in 40 CFR Part 63, Subpart WWWWW apply to any existing or new hospital EtO sterilization facility that is an area source of HAP. The owner or operator of an existing area source was required to comply with this area source NESHAP by December 29, 2008. The owner or operator of a new area source must comply with this area source NESHAP upon initial startup.

3.4.5 Polyether Polyols Production NESHAP

The NESHAP found in 40 CFR Part 63 Subpart PPP apply to any existing or new polyether polyol production facilities that use an epoxide compound and emit EtO. The final NESHAP rule establishes emission limits and control efficiency requirements for the following aspects of the manufacturing process: storage tanks, process vents, equipment leaks, and wastewater treatment systems.

3.4.6 Area Sources

USEPA is considering taking action based on the recommendations in the 2020 report issued by the Office of Inspector General (USEPA 2021e).

3.4.7 Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA)

Tolerances for EtO and ECH are established under 40 CFR 180.151. This regulation is under revision and on March 28, 2023, USEPA released the Proposed Interim Registration Review Decision for EtO as it relates to pesticide use (USEPA 2023aa).

Under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), USEPA regulates the use of EtO as a sterilant (EtO is considered an antimicrobial and conventional pesticide). USEPA evaluates a wide variety of potential human health and environmental effects associated with the use of a pesticide through the registration review process(USEPA 2023aa). USEPA conducts this process, for all currently registered pesticides at least every 15 years to ensure that products can carry out their intended function without creating unreasonable risks to human health and the environment (USEPA 2022l). The EtO registration is currently undergoing review. As part of the FIFRA registration review for EtO, USEPA is continuing to assess potential human health risks, including those that come from working in facilities that use EtO or from living in communities near facilities that use EtO (USEPA 2020b).

In April 2023, USEPA released both a proposed interim decision for EtO and a draft risk assessment addendum that provides additional information on cancer risks from EtO (USEPA 2023aa).

USEPA’s Office of Pesticide Programs, which implements FIFRA, notes that MEG and ethylene chlorohydrin (ECH) form as hydrolysis reaction byproducts of EtO fumigation (see Figure 2). ECH is formed in EtO-fumigated commodities whenever a chloride ion is present (USEPA 2020c).

3.4.8 Federal Initiatives

3.4.8.1 United States Food and Drug Administration (FDA)

All sterilization operations of medical devices in the United States must use a validated sterilization process that meets internationally agreed upon voluntary consensus standards recognized by the FDA Center for Devices and Radiological Health (CDRH) (FDA 2023a). Sterilized medical devices must not exceed EtO or ECH levels as described in ISO Standard 10993:7. “The FDA is actively working with sterilization experts, medical device manufacturers, and other government agencies to advance innovative ways to sterilize medical devices with lower levels of currently used agents, and employ new agents or alternatives, while maintaining device safety and effectiveness” (FDA 2023b). Advances may include using lower levels of sterilization agents and employing new agents or alternatives, all while maintaining device safety and effectiveness.

The goal of the FDA CDRH Sterilization Master File Pilot Programs is to help “ensure patients have access to safe medical devices and encourage new, innovative ways to sterilize medical devices that reduce the potential impact of EtO on the environment and on public health” (FDA 2023b). In 2019, the FDA CDRH announced two public innovation challenges (FDA 2023b)to encourage the development of new sterilization methods to reduce EtO emissions:

- Challenge 1: Identify New Sterilization Methods and Technologies (FDA 2019a)

The goal of this challenge is to encourage the development of new approaches to device sterilization methods or technologies for medical devices that do not rely on EtO (FDA 2023b).

- Challenge 2: Reduce Ethylene Oxide Emissions (FDA 2019b)

The goal of this challenge is to develop strategies or technologies to reduce emissions from the EtO sterilization process to as close to zero as possible (FDA 2023b).

3.4.8.2 USEPA

Annually, the USEPA issues solicitations for Phase 1 and Phase II research proposals from science and technology firms. Phase II contracts are limited to small businesses that have successfully completed their Phase I projects. This Small Business Innovation Research Program aims to fund research into topics of broad interest to the scientific community to develop and commercialize innovative technologies (USEPA 2023ad). In 2021 and 2022 the solicitation included calls for novel EtO measurement technologies. Companies were awarded Phase I and Phase II grants to develop instrumentation (some of which are discussed in Section 6) to measure EtO over a wide range of concentrations from ambient environments to in-stack, source environments. A list of awardees is posted on the USEPA SBIR website (USEPA 2023p).

3.4.9 OSHA’s EtO Resources

The Occupational Safety and Health Administration (OSHA) was created to “ensure safe and healthful working conditions for workers by setting and enforcing standards and by providing training, outreach, education, and assistance” (OSHA 2023a). Follow the links below for EtO-related workplace information:

- Ethylene Oxide Overview (OSHA 2023c)

- Occupational Safety and Health Administration EtO Fact sheet (OSHA 2002)

- ASTM International Method D5578-04(2015) – Method by which OSHA determines EtO in workplace atmospheres (ASTM 2016)

3.5 How are Individual States Addressing EtO?

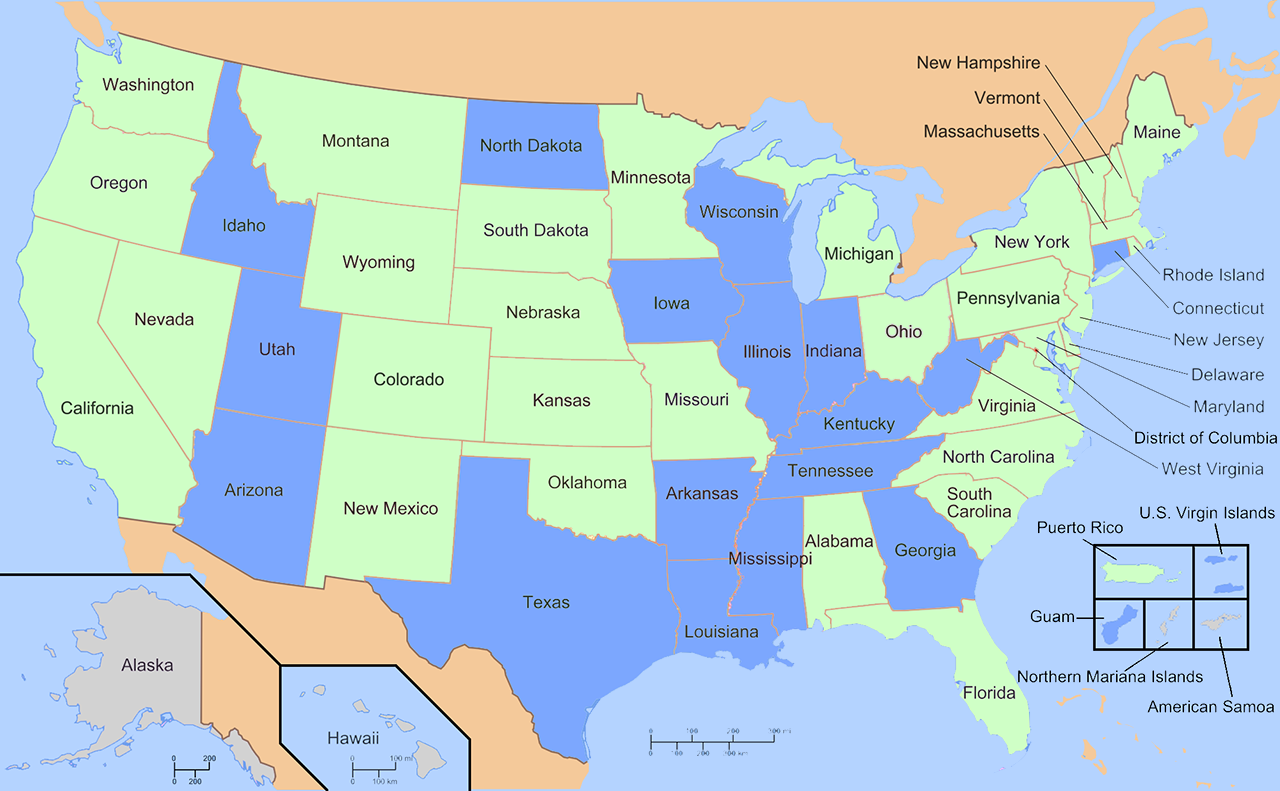

State regulatory agencies often have the delegated authority to regulate and enforce environmental and public health requirements. The 50 states have different priorities, resources, and processes. Several states have been actively involved with addressing EtO emissions across multiple regulatory programs. Click on the map for detailed state information, including fact sheets, state delegation, USEPA information, and county-specific information (Figure 4).

Alabama

State Delegation on EtO

Alabama Department of Environmental Management, Air Program

USEPA Information

Part 63 National Emission Standards for Hazardous Air Pollutants (NESHAP) (2021)

County-Specific Information

City of Huntsville Department of Natural Resources

Alaska

Arizona

State Delegation on EtO

AZDEQ NESHAPs and NSPS

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

CAA Permitting in EPA's Pacific Southwest (Region 9) | US EPA

County-Specific Information

Maricopa County

Arkansas

California

State Delegation on EtO

FINAL REGULATION ORDER , ETHYLENE OXIDE AIRBORNE TOXIC CONTROL MEASURE

Ethylene Oxide Airborne Toxic Control Measure (ATCM)

CA: South Coast Air Quality Management District - Proposed Amended Rule 1405 (aqmd.gov)

USEPA Information

US EPA Regulations for Ethylene Oxide

Ethylene Oxide Commercial Sterilization Facilities | US EPA

CAA Permitting in EPA's Pacific Southwest (Region 9) | US EPA

Fact Sheets

Ethylene Oxide (EtO) Fact Sheet (2008)

Colorado

State Delegation on EtO

Ethylene oxide and Terumo BCT | Department of Public Health & Environment (colorado.gov)

USEPA Information

Air Toxics Screening Assessment

Lakewood, Colorado (Terumo BCT Sterilization Service, Inc.)

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Community risk assessment of ethylene oxide near

Connecticut

Delaware

Florida

State Delegation on EtO

62-210.310 : Air General Permits - Florida Administrative Rules, Law, Code, Register - FAC, FAR, Rulemaking (flrules.org)

USEPA Information

Ethylene Oxide Emissions Standards for Sterilization Facilities: National Emission Standards for Hazardous Air Pollutants (NESHAP) | US EPA

Groveland, Florida (International Sterilization Laboratory)

Ethylene Oxide Commercial Sterilization Facilities | US EPA

Frequent Questions about Ethylene Oxide (EtO) | US EPA

County-Specific Information

Groveland, FL

https://www.epa.gov/fl/temple-terrace-fl-american-contract-systems

Fort Myers, FL (American Contract Systems (Fort Myers Facility)) | US EPA

Georgia

State Delegation on EtO

AIR PROTECTION BRANCH 2020 Air Quality Report

USEPA Information

Subject 391-3-1 AIR QUALITY CONTROL, Rule 391-3-1-.01 Definitions. Amended

Georgia EPD Comments on 2017 AirToxScreen

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Ethylene oxide: Technical Reviews and Outreach to Potentially Affected Communities Status Report -- Sterigenics Cobb County, Smyrna, Georgia

Hawaii

State Delegation on EtO

Clean Air Branch (hawaii.gov)

USEPA Information

CAA Permitting in EPA's Pacific Southwest (Region 9) | US EPA

Idaho

State Delegation on EtO

IDAPA 58 - Department of Environmental Quality. Book (idaho.gov)

Illinois

State Delegation on EtO

Public Act 101-0022, Illinois General Assembly

Public Act 101-0023, Illinois General Assembly (2019)

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

Indiana

Iowa

State Delegation on EtO

CHAPTER 22 CONTROLLING POLLUTION

USEPA Information

Air Toxics: EPA Updates Several Regulations

Air Toxics Update: Miscellaneous Organic Chemical Manufacturing (MON) (2020)

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Air Quality - Polk County Iowa

Outdoor Air Quality | Linn County, IA - Official Website (linncountyiowa.gov)

Air Toxics | Linn County, IA - Official Website (linncountyiowa.gov)

Kansas

State Delegation on EtO

KS-Air-Quality-Regulations-PDF

USEPA Information

Delegation of Authority in Kansas for New Source Performance Standards and National Emission Standards for Hazardous Air Pollutants | US EPA

County-Specific Information

https://www.wycokck.org/Departments/Health/Clean-Safe-Places/Air-Quality

Kentucky

State Delegation on EtO

Title 401 Chapter 59 Regulation 090 • Kentucky Administrative Regulations • Legislative Research Commission

USEPA Information

Title 401 Chapter 57 Regulation 002 • Kentucky Administrative Regulations • Legislative Research Commission

County-Specific Information

Regulation 5.14 Version 8 Hazardous Air Pollutants and Source Categories Louisville Metro Air Pollution Control District 2012 (louisvilleky.gov)

Louisiana

State Delegation on EtO

TITLE 33 Part III. Air (2013)

USEPA Information

Air Issues in Louisiana | US EPA

Maine

State Delegation on EtO

https://www.maine.gov/dep/air/monitoring/index.html

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Findings of Fact Amendment #1. Jackson Laboratory, Hancock County, Maine. State of Main DEP

Findings of Fact Amendment #5. Jackson Laboratory, Hancock County, Maine. State of Main DEP

Maryland

State Delegation on EtO

Toxic Air Pollutant Regulations Assistance (maryland.gov)

2012-Revised-TAP-Screening-Levels-cas-sort.pdf (maryland.gov)

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

Fact Sheets

Title 5 Fact Sheet (maryland.gov)

County-Specific Information

Hanover, MD

Massachusetts

State Delegation on EtO

Massachusetts Department of Environmental Protection (MassDEP) Top Case BACT Guidelines For MECHANICAL AND MISCELLANEOUS SOURCES

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

Fact Sheets

Massachusetts Toxics Use Reduction Institute, Ethylene Oxide Fact Sheet

County-Specific Information

Taunton, MA

Michigan

State Delegation on EtO

Fact Sheets

Ethylene Oxide Air Emissions Viant Medical Inc. Frequently Asked Questions (2019)

Minnesota

State Delegation on EtO

Minnesota Rules 2020, Chapter 7007 (mn.gov)

USEPA Information

Minnesota Administrative Rules 7011.7140 INCORPORATION BY REFERENCE; EMISSION STANDARDS; ETHYLENE OXIDE FOR STERILIZERS.

Ethylene Oxide Commercial Sterilization Facilities | US EPA

Fact Sheets

Facts about Air Quality Permit Rules (2010)

Mississippi

Missouri

State Delegation on EtO

Area Sources and Standards | Missouri Department of Natural Resources (mo.gov)

Missouri Secretary of State: Code of State Regulations (mo.gov)

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Jackson, MO

Montana

State Delegation on EtO

Administrative Rules of the State of Montana (mt.gov)

Nebraska

State Delegation on EtO

AIR QUALITY REGULATIONS STATE OF NEBRASKA DEPARTMENT OF ENVIRONMENTAL QUALITY - TITLE129 6-15-11.DOC (ne.gov)

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Columbus, NE

Nevada

State Delegation on EtO

NAC: CHAPTER 445B - AIR CONTROLS (state.nv.us)

USEPA Information

Lincoln-Lancaster County Health Department Air Quality Program 40 CFR Part 63 Subpart WWWWW – Initial Notification / Notification of Compliance Status

Ethylene Oxide Commercial Sterilization Facilities | US EPA

CAA Permitting in EPA's Pacific Southwest (Region 9) | US EPA

New Hampshire

State Delegation on EtO

https://www.des.nh.gov/air/industrial-sources/air-toxics-compliance

New Jersey

State Delegation on EtO

NJ EtO reporting guidelines

https://dep.nj.gov/airquality/

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

Fact Sheets

FACT SHEET Ethylene Oxide (EtO) Air Emissions from Commercial Sterilizers (2022)

Hazardous Substance Fact Sheet, Ethylene Oxide (revised 2016)

County-Specific Information

Franklin , NJ

New Mexico

State Delegation on EtO

83-FR-15964-EPA-Delegation-to-NM.pdf

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

New York

North Carolina

State Delegation on EtO

SECTION .0500 - EMISSION CONTROL STANDARDS (pg. 53)

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

FORSYTH COUNTY, NORTH CAROLINA

Appendices to the Forsyth County, NC, Air Quality Control Code and Air Quality Technical Code (2000)

North Dakota

Ohio

Oklahoma

State Delegation on EtO

Federal Register / Vol. 87, No. 139 / Thursday, July 21, 2022 / Rules and Regulation

Revisions to SIP for State of Oklahoma (epa.gov)

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Ardmore, OK

Oregon

Pennsylvania

State Delegation on EtO

Emission Standards (pa.gov)

USEPA Information

PADEP Comments to EPA EtO ANRPM.pdf (state.pa.us)

Technical Air Pollution Resources | US EPA

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Erie, PA

Rhode Island

State Delegation on EtO

RI DEM/Air Resources- Air Pollution Control Regulation No. 22- Air Toxics

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

South Carolina

South Dakota

Tennessee

Texas

USEPA Information

40 CFR Part 63 - National Emission Standards for Hazardous Air Pollutants for Source Categories (a.k.a. Maximum Achievable Control Technology (MACT))

40 CFR Part 63 Subpart WWWWW -- National Emission Standards for Hospital Ethylene Oxide Sterilizers

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Athens, TX

Utah

USEPA Information

Ethylene Oxide in Utah - Utah Department of Environmental Quality

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Sandy, UT

Vermont

State Delegation on EtO

STATE OF VERMONT AGENCY OF NATURAL RESOURCES, AIR POLLUTION CONTROL REGULATIONS (2018)

County-Specific Information

1382.doc (live.com)

Virginia

State Delegation on EtO

Department of Veterans Affairs Veterans Health Administration, Safe use of Ethylene Oxide (2017)

Virginia Register of Regulations Vol. 2 Iss. 11

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Henrico, VA

Washington

State Delegation on EtO

Chapter 173-401 WAC: Thresholds for hazardous air pollutants.

County-Specific Information

Benton Clean Air Agency

SWCAA Permits (swcleanair.gov)Permits & Registration | Puget Sound Clean Air Agency, WA (pscleanair.gov)

Permits and Services | Northwest Clean Air Agency (nwcleanairwa.gov)

Air Operating Permits - Spokane Regional Clean Air Agency (spokanecleanair.org)

Yakima County Air Quality - Yakima Regional Clean Air Agency (yakimacleanair.org)

West Virginia

Wisconsin

Wyoming

State Delegation on EtO

Environmental Quality, Dept. of Air Quality, Chapter 5: National Emission Standards

American Samoa

Commonwealth of the Northern Mariana Islands

Guam

Puerto Rico

State Delegation on EtO

Amendments-7985-for-the-Regulation-for-the-Control-of-Atmospheric-Air-Pollution-Reg-5300.pdf (pr.gov)

Regulations-for-the-Control-of-Atmospheric-Pollution-RCAP-1995-Regulation-No-5300.pdf (pr.gov)

USEPA Information

Ethylene Oxide Commercial Sterilization Facilities | US EPA

County-Specific Information

Añasco, PR

US Virgin Islands

Delegation Key:

– no delegation

– delegation

– delegation + extra info/state info/USEPA info

Figure 4. Interactive EtO Regulations, Resources, and Processes tool.

Figure 4 PDF File

4. Sources of EtO

4.1 Introduction

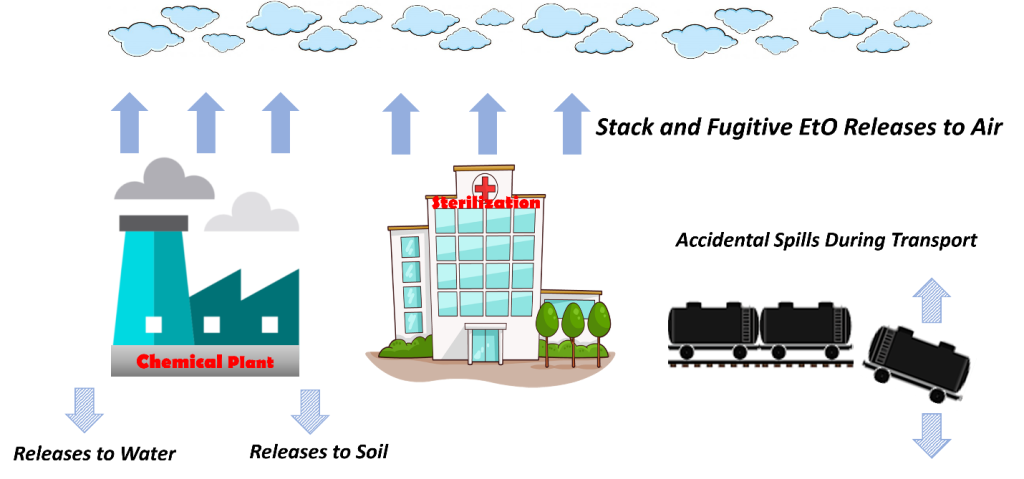

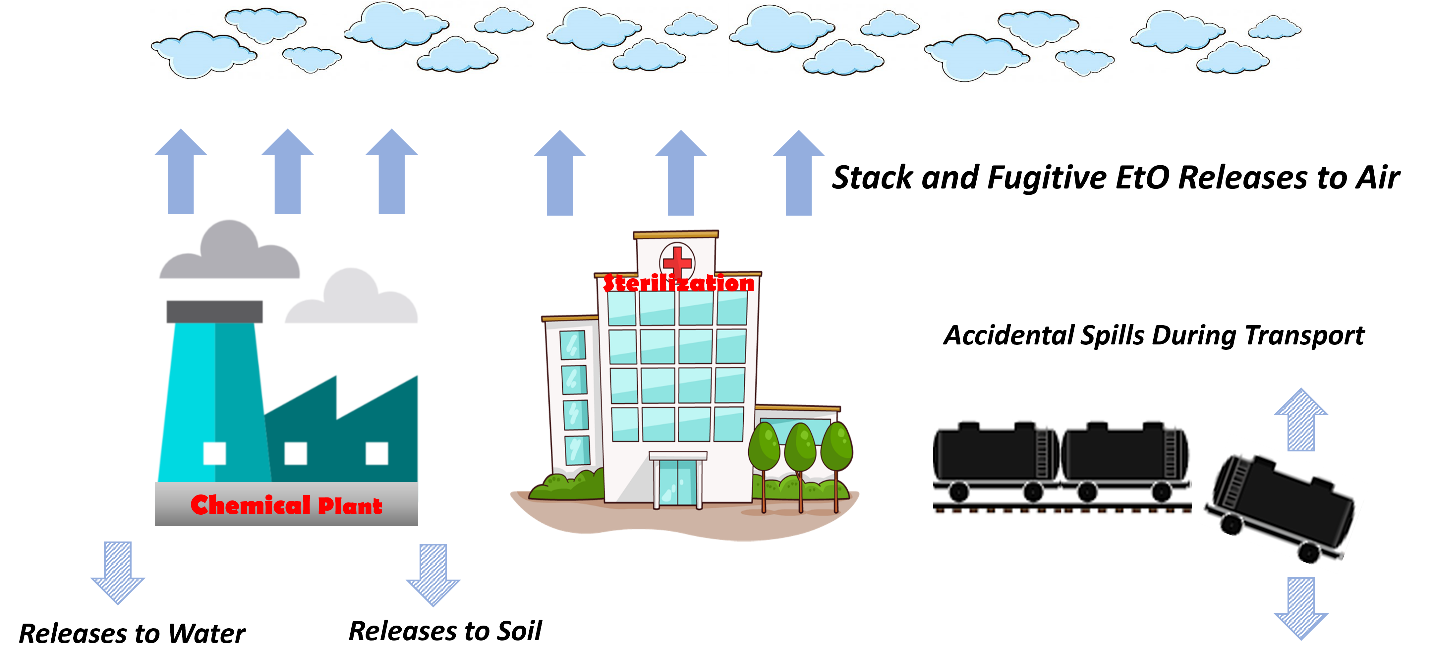

EtO is best known for its uses in chemical manufacturing and sterilization. There are several known and potential sources of EtO and different ways it can be released into the environment, such as from industrial or sterilization facilities (Figure 5). Releases of EtO to air are a primary concern due to the health risks associated with inhalation exposure. This section describes available data on releases of EtO to the environment, known sources of EtO emissions to air, and potential sources of EtO emissions to air.

4.2 Data on Releases of EtO to the Environment

EtO releases to the environment are recorded under the USEPA TRI Program (USEPA 2023ag). The TRI Program encompasses several hundred toxic chemicals that may pose a threat to human health and the environment and supports informed decision-making by communities, governments, and industry. Specifically, TRI reflects annual reporting requirements for EtO use and stack and fugitive releases (Scientific Control Laboratories 2019). Users and stationary manufacturing facilities are required to report this information as well as all occasional accidental spills greater than 10 pounds (PHMSA 1998, USEPA 2022d) that occur as a result of transport or packaging activities (see Figure 5) (49 CFR 171.15 2003). In December 2021, USEPA extended TRI reporting requirements for EtO releases to include certain contract sterilization facilities that had previously not been required to report (USEPA 2021d). More information about incident reporting can be found at this link (USDOT 2019).

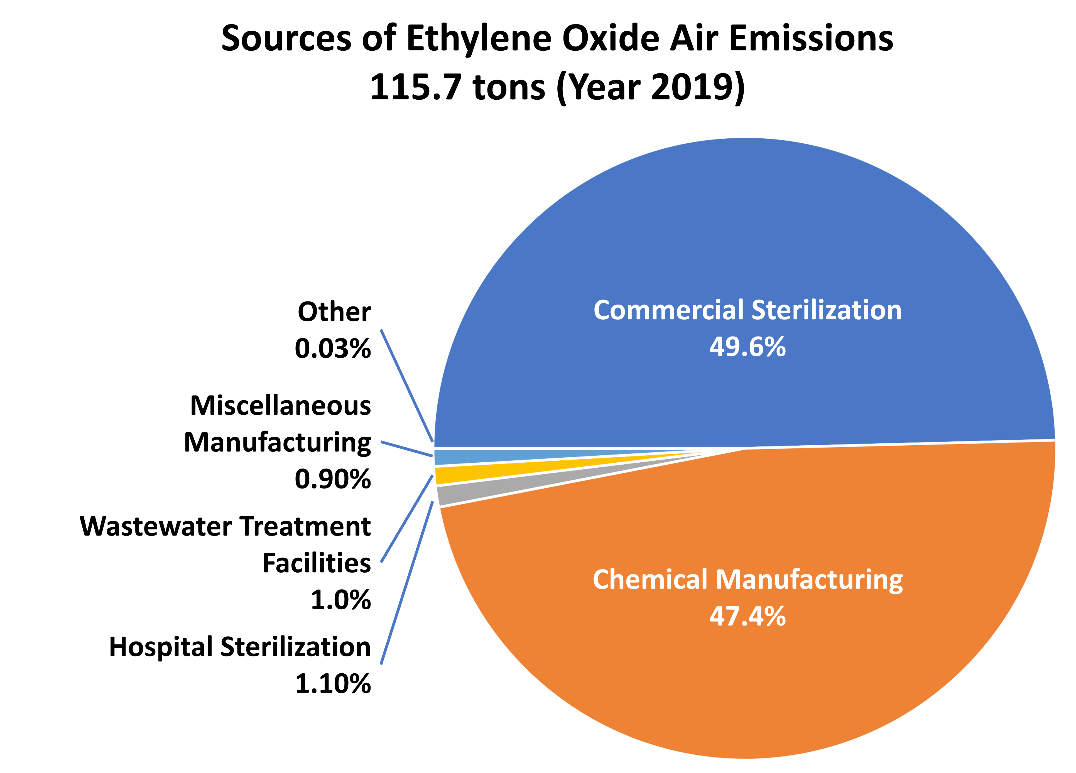

The Air Toxics Screening Assessment (AirToxScreen) (USEPA 2023h) is USEPA’s screening tool to provide communities with information about health risks from air toxics, which is based on the IRIS value (see Section 2.4 for more information). At the time of this writing, the most current version of AirToxScreen uses 2019 data. The 2019 AirToxScreen includes HAP emissions from the 2017 National Emissions Inventory (NEI) and USEPA emissions estimates of EtO from commercial sterilizers. The NEI consists of estimated emissions of criteria pollutants, criteria precursors, and HAP that USEPA collects from state, local, and tribal air agencies. USEPA augments this data set with other data sources, including the TRI. At the time of this writing, the 2020 NEI has the most current set of EtO emissions data, which will be incorporated into the 2020 AirToxScreen.

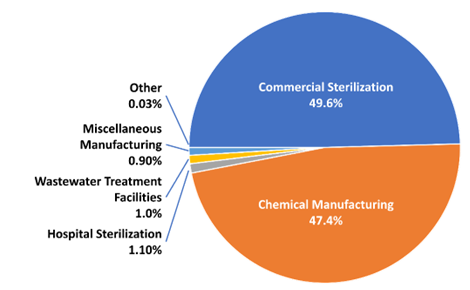

Other than the sterilizer data, almost all EtO data in the NEI are from facility-total stack and facility-total fugitive emissions that have been reported to state, local, and tribal agencies who then report to USEPA. Additional data about EtO emissions comes from the TRI (USEPA 2022b). AirToxScreen also includes 0.97 tons of EtO from nonpoint wastewater treatment (using the same 2017 NEI estimate because nonpoint activity and emissions are surveyed every three years). The 2019 commercial sterilizer emissions estimates are based on industry responses to USEPA’s information collection requests of December 2019 and September 2021 associated with a risk and technology review (RTR) proposal to amend the NESHAP for commercial sterilizers. The same methodology was used to estimate emissions for modeling risk in this rulemaking. Commercial sterilizer EtO emissions estimates in 2017 and 2018 AirToxScreen were prepared like those for 2019 AirToxScreen but were based on the activity and emissions controls operating for each calendar year. Figure 6 includes TRI, NEI, and RTR data, which are the most up-to-date publicly available information on these sources (USEPA 2021b). The percent contribution of emissions by industries varies from year to year.

AirToxScreen emissions point source spreadsheet contains point source emissions, including EtO emissions, by facility, with facility IDs, county, state, and facility coordinates (USEPA 2021b).

Facility emissions were reported to USEPA by state and local agencies. For facilities where EtO emissions were not reported in the emissions inventory process, USEPA obtained the data from the 2019 TRI. For facilities where EtO emissions were not available in the 2019 TRI, USEPA obtained the data from the 2017 NEI. In addition, USEPA amended these data by using more current information about 2019 emissions from the Commercial Sterilizers RTR analysis. Emissions were categorized by industry type based on the North American Industry Classification System (NAICS) code reported for each facility or source classification code reported for each process. While the 2019 AirToxScreen data set is the most recent available, it may not account for EtO emissions from all facilities that emit EtO because some of these facilities are not subject to federal, state, local, or TRI emission reporting requirements. TRI reporting requirements can be found here (USEPA 2023ah).

4.3 Known Sources of EtO

4.3.1 Sterilization Sources

The FDA states that “use of ethylene oxide is a well-established and scientifically-proven method of preventing harmful microorganisms from reproducing and causing infections without degrading the product, unlike some other sterilization methods” (FDA 2022). Further, “more than 20 billion devices sold in the U.S. every year are sterilized with ethylene oxide, accounting for approximately 50% of devices that require sterilization. These devices range from wound dressings to more specialized devices, such as stents, as well as kits used in routine hospital procedures or surgeries that include multiple components made from different materials. Inadequate sterilization can lead to life-threatening infections in patients undergoing a wide range of medical procedures” (FDA 2022).

Sterilization with EtO is used for medical devices and equipment, laboratory equipment, dried herbs and spices, and pest control of imported goods when the objects being sterilized cannot withstand high temperature treatment moisture or otherwise destructive characteristics of available sterilization alternatives (i.e., irradiation, steam, etc.). This process requires a chamber to control variables such as temperature, time, concentration, and pressure.

4.3.1.1 Commercial Sterilization

Commercial sterilization can be broken into two categories: large scale and small scale. The differentiating factors between the categories are the size of EtO containers used and permitting requirements. Small-scale sterilization uses either cartridges or bottles to deploy EtO into the chamber, whereas large-scale sterilization uses either cylinders or drums of EtO.

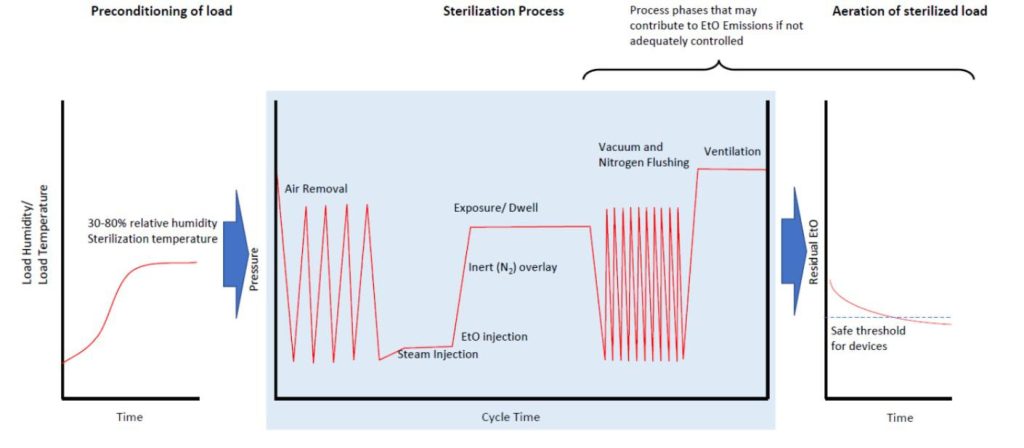

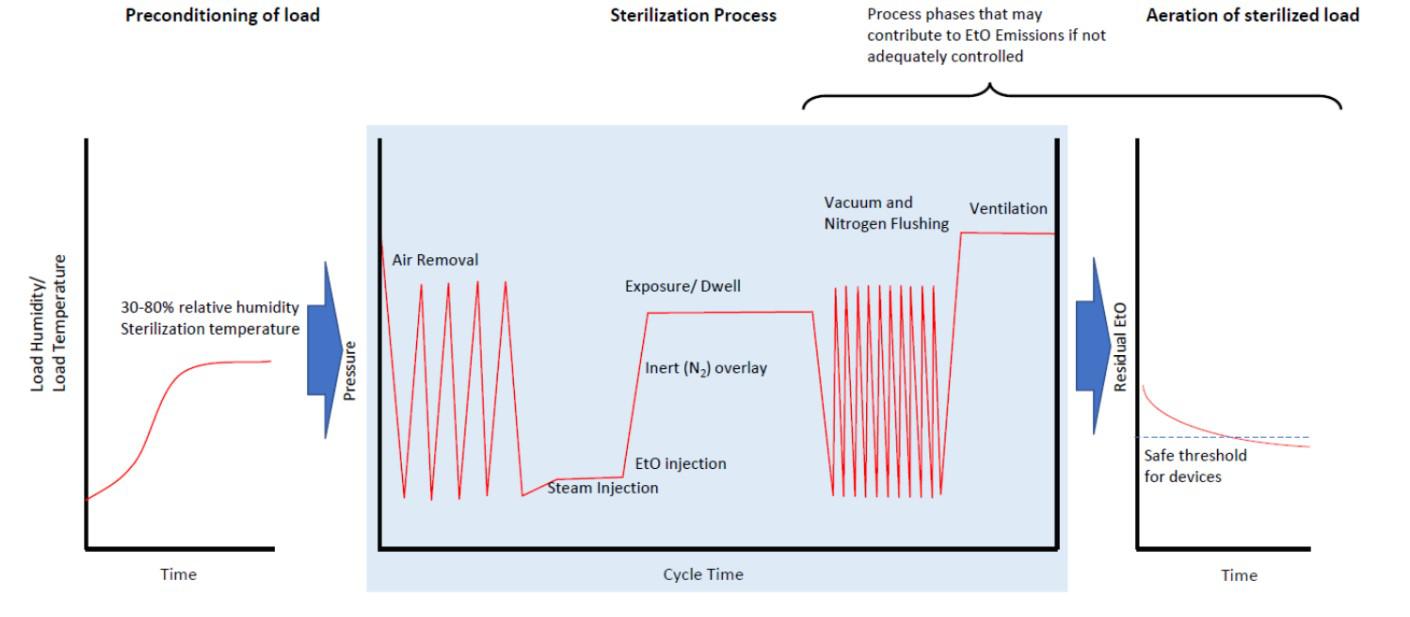

Typical commercial sterilization follows the same process: preconditioning, sterilization, and aeration (Figure 7). A more detailed description of the sterilization process can be found at this FDA webpage (FDA 2019c).

4.3.1.2 Medical Equipment Sterilization

Many medical care facilities have all-in-one sterilization chambers (i.e., sterilization and aeration occur in one chamber) that may be similar to commercial sterilizer chambers. These types of facilities only sterilize equipment that will be used within the medical facility and generally work on a smaller scale than a commercial sterilization operation (e.g., benchtop sterilization unit).

4.3.1.3 Fumigation/Spice/Pest

Bulk dried herbs and spices are sterilized in chambers using processes similar to those used in commercial sterilizers (USEPA 2023ab).

4.3.1.4 Noncommercial Benchtop Sterilization

Several manufacturers sell benchtop EtO sterilizers that can be used at smaller facilities such as surgical centers, dental offices, veterinary clinics, tattoo parlors, and nail salons. As of the publication of this guide, sterilization using EtO in these settings is not well documented; however, it is not expressly prohibited under FIFRA. Follow this link for a video on the benchtop sterilization process (DLEAH 2020).

4.3.2 Chemical Manufacturing Sources

The chemical manufacturing sector converts EtO from raw material into many commercial and industrial products (see Section 2.2). Stack and fugitive emissions may be produced before and during conversion of EtO into other products. Stack emissions can be effectively controlled with a variety of control technologies (for more information, see Section 5). Fugitive emissions are typically managed by leak detection and repair.

4.3.3 Fugitive Emissions

Defined in 40 CFR 63.2, fugitive emissions are “those emissions that could not reasonably pass through a stack, chimney, vent, or functionally equivalent opening.” As stated in the American Chemistry Council (ACC) EtO product stewardship guidance manual, “fugitive emissions include equipment leaks, evaporative losses from surface impoundments, spills, and releases from building ventilation systems. EtO fugitive emissions may be calculated rather than measured” (ACC 2023b, 33). Examples of this could include mass balance or calculations based on gas laws. The ACC also states that “In some instances, measurements are used to validate calculations. In some cases, fugitive emissions can be a large contributor to reported emissions” (ACC 2023b, 33).

As discussed in Section 3, state and federal regulations limit EtO emissions. The MON, for example, sets “emission limits and work practice standards for new and existing miscellaneous organic chemical manufacturing process units, wastewater treatment and conveyance systems, transfer operations, and associated ancillary equipment” (USEPA 2023t). For the chemical manufacturing sector, federal regulations for leak detection and repair cover the frequency and protocol for monitoring valves, connectors, pump seals, compressors, and other fugitive emission sources and require corrective actions, as appropriate (see Section 3.4 of this guide for more information). On April 25, 2023, USEPA proposed a standard for fugitive emissions from commercial sterilization and fumigation operations; however, those regulations are under development. Efforts to evaluate emissions from products post-sterilization outside of sterilization facilities (e.g., in warehouses or storage locations) are ongoing, and additional work is needed.

Residual emissions and off-gassing of EtO from treated medical devices and dried herbs and spices are not expected to be a concern for consumers (USEPA 2022g). Refer to USEPA’s Ethylene Oxide National Public Webinar for more information (USEPA 2022h).

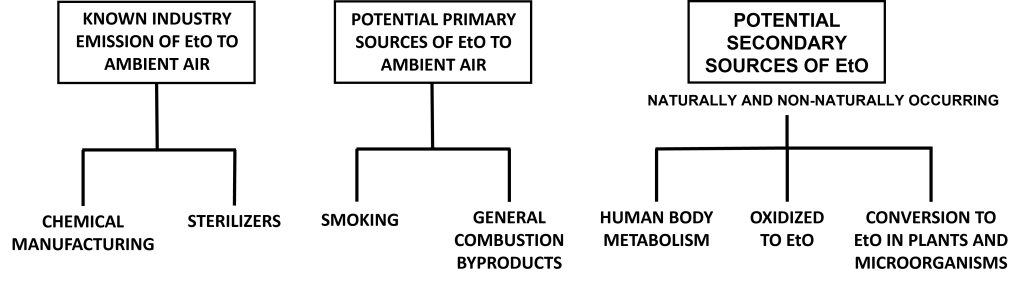

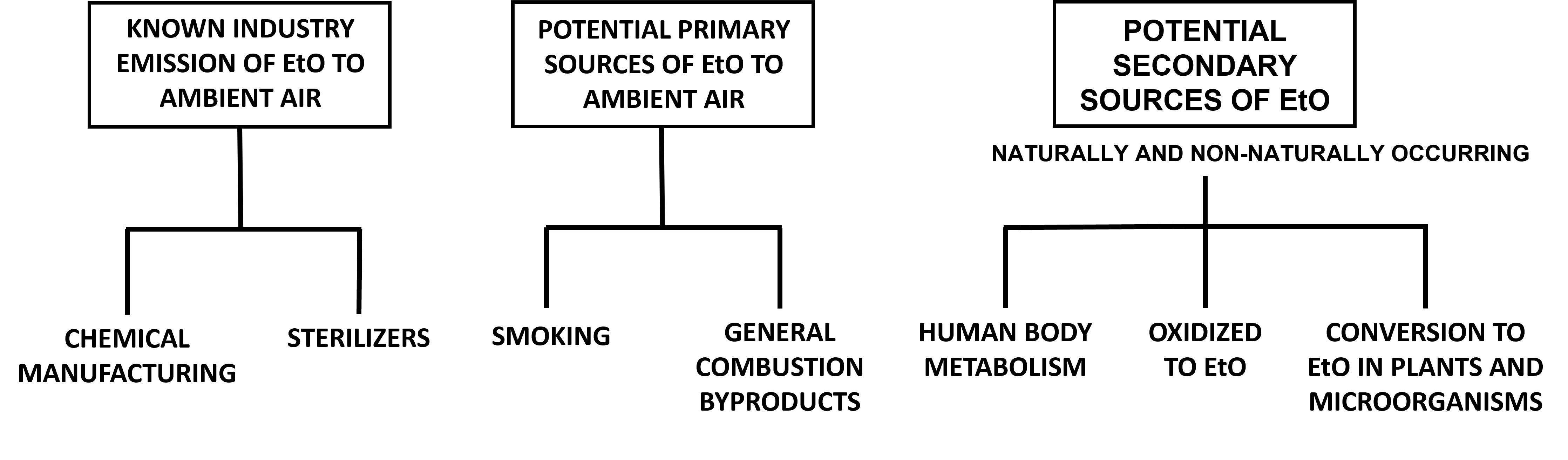

4.4 Potential Sources

The potential contributions of EtO to the atmosphere by nonindustrial sources has received little study and is an emerging area of science. Several types of potential EtO sources have been mentioned in this guide (Figure 8), and these sources of EtO are expected to vary over time as relevant economic and environmental conditions change and technical knowledge is accumulated. This guide attempts to cover these potential sources and provide examples of the EtO science that is better understood. This information is subject to change in the future.

Figure 8 does not represent the magnitude of source contributions. Image is not to scale and does not represent equivalence in contributions. These sources are documented in Section 4 and appendix. Please click the text in the figure for more information on these sources.

EtO can be created via several chemical and biological mechanisms identified in microbes, plants, and animals (for more information, see appendix). Not all of the chemical mechanisms are well studied or understood because these reactions can be either primary or secondary sources of EtO. For the purposes of this guide, secondary sources are those that require metabolism or a chemical reaction to produce EtO.

In simplest terms EtO is an oxidation product of ethylene (C2H4) or ethane (C2H6). Ethylene is a precursor to the formation of EtO, as well as other chemicals that are not discussed in this guide. Ethylene is a reactive chemical intermediate and an important naturally occurring plant hormone and is also a known byproduct of combustion. Ethylene can be converted to EtO through chemical and biological processes. The extent to which the conversion of ethylene to EtO occurs is currently not fully understood.

More research is necessary to better understand the pathways. They could be a direct conversion or part of a more complex reaction that potentially involves other VOCs or particles and photochemical reactions in the air.

Endogenous creation of EtO can occur in microbes, plants, and animals. In plants, enzymatic oxidation of ethylene, a phytohormone in plants, is the first step to create EtO, glucose derivatives, or MEG and CO2 (see appendix and Beyer (1984)).

Work is currently being done to identify nonindustrial contributions of EtO in forested rural locations. For example, South Carolina (SCDHEC 2019) and Georgia (GAEPD 2019) have both been working with federal funds to learn more about the presence of EtO in these areas.

4.4.1 Combustion Byproduct

Some evidence suggests that EtO can be emitted as a combustion byproduct (Kirman et al. 2021) (Figure 9). Because of concerns about potential toxicity from EtO formed through combustion, additional research is needed to determine whether EtO is a byproduct of combustion. If it is, further investigation is necessary to determine the potential emission rates from different types of combustion processes and fuel combinations.

This work can better inform the potential risk to those with the highest exposure to combustion emissions. Descriptions of several combustion sources and information about their potential EtO emissions are provided below.

4.4.1.1 Cigarette Smoke and Vaping

Cigarette smoke (Figure 10) contains more than 70 carcinogens, potentially including EtO (ATSDR 2022d, CDC 2019). Based on elevated levels of EtO hemoglobin adducts in blood samples from smokers compared to the general population, the Agency for Toxic Substances and Disease Registry (ATSDR) suggests that EtO is present in cigarette smoke (CDC 2022, Filser et al. 1992, Jain 2020). A recent literature review (Kirman et al. 2021) provides an overview of the characterization of potential total exposure to EtO via endogenous and exogenous pathways. Studies have also shown that e-cigarettes have been found to contain some of the same carcinogenic compounds as traditional cigarettes. In several studies, analysis of the short-term urinary mercapturic acid metabolite of EtO (HEMA) in e-cigarette users and traditional tobacco smokers reported elevated levels of this metabolite, compared to nonsmokers (Eckert et al. 2011, Frigerio et al. 2020, Jacob et al. 2013, Rubinstein et al. 2018).

4.4.1.2 Wildfires and Prescribed Burning

Emission of EtO is not a known component of smoke from wildfires or prescribed fires (USEPA 2021a, 7-11 to 7-13, Tables 7-8 and 7-9). If EtO is emitted as a byproduct of combustion, then it is possible that combustion of biomass, such as from wildfires, could be a potential source. More research is needed to determine whether this is the case.

4.4.1.3 Fuel Combustion in Mobile and Stationary Sources

A wide variety of fuels such as natural gas, fuel oils, gasoline, coal, and wood are combusted to power both on-road and nonroad motor vehicles, as well as to provide heat and electricity for buildings, homes, and industrial processes. Few published studies focus on EtO emissions from mobile and stationary combustion sources. USEPA currently notes that EtO emissions from mobile exhaust have not been confirmed, but they are working to develop test methods that will allow careful evaluation of this potential combustion source to determine the extent to which EtO may be emitted (USEPA 2023a)

4.1 Introduction

EtO is best known for its uses in chemical manufacturing and sterilization. There are several known and potential sources of EtO and different ways it can be released into the environment, such as from industrial or sterilization facilities (Figure 5). Releases of EtO to air are a primary concern due to the health risks associated with inhalation exposure. This section describes available data on releases of EtO to the environment, known sources of EtO emissions to air, and potential sources of EtO emissions to air.

4.2 Data on Releases of EtO to the Environment

EtO releases to the environment are recorded under the USEPA TRI Program (USEPA 2023ag). The TRI Program encompasses several hundred toxic chemicals that may pose a threat to human health and the environment and supports informed decision-making by communities, governments, and industry. Specifically, TRI reflects annual reporting requirements for EtO use and stack and fugitive releases (Scientific Control Laboratories 2019). Users and stationary manufacturing facilities are required to report this information as well as all occasional accidental spills greater than 10 pounds (PHMSA 1998, USEPA 2022d) that occur as a result of transport or packaging activities (see Figure 5) (49 CFR 171.15 2003). In December 2021, USEPA extended TRI reporting requirements for EtO releases to include certain contract sterilization facilities that had previously not been required to report (USEPA 2021d). More information about incident reporting can be found at this link (USDOT 2019).

The Air Toxics Screening Assessment (AirToxScreen) (USEPA 2023h) is USEPA’s screening tool to provide communities with information about health risks from air toxics, which is based on the IRIS value (see Section 2.4 for more information). At the time of this writing, the most current version of AirToxScreen uses 2019 data. The 2019 AirToxScreen includes HAP emissions from the 2017 National Emissions Inventory (NEI) and USEPA emissions estimates of EtO from commercial sterilizers. The NEI consists of estimated emissions of criteria pollutants, criteria precursors, and HAP that USEPA collects from state, local, and tribal air agencies. USEPA augments this data set with other data sources, including the TRI. At the time of this writing, the 2020 NEI has the most current set of EtO emissions data, which will be incorporated into the 2020 AirToxScreen.

Other than the sterilizer data, almost all EtO data in the NEI are from facility-total stack and facility-total fugitive emissions that have been reported to state, local, and tribal agencies who then report to USEPA. Additional data about EtO emissions comes from the TRI (USEPA 2022b). AirToxScreen also includes 0.97 tons of EtO from nonpoint wastewater treatment (using the same 2017 NEI estimate because nonpoint activity and emissions are surveyed every three years). The 2019 commercial sterilizer emissions estimates are based on industry responses to USEPA’s information collection requests of December 2019 and September 2021 associated with a risk and technology review (RTR) proposal to amend the NESHAP for commercial sterilizers. The same methodology was used to estimate emissions for modeling risk in this rulemaking. Commercial sterilizer EtO emissions estimates in 2017 and 2018 AirToxScreen were prepared like those for 2019 AirToxScreen but were based on the activity and emissions controls operating for each calendar year. Figure 6 includes TRI, NEI, and RTR data, which are the most up-to-date publicly available information on these sources (USEPA 2021b). The percent contribution of emissions by industries varies from year to year.

AirToxScreen emissions point source spreadsheet contains point source emissions, including EtO emissions, by facility, with facility IDs, county, state, and facility coordinates (USEPA 2021b).